製品概要

EKSPLA社製は、長年に渡りレーザ及びレーザに関する電気機器の製造・販売を行っており、常に最先端の製品を世に送り出しています。

特にハイパワーエレクトロニクス(高速/高電圧電源)は、EKSPLAが得意とするコア技術の一つです。

R&DからOEMまでと幅広い用途に対応するために、お客様のご要望に応じたカスタマイズも承っておりますので、お気軽にお問い合わせください。

PS1223CO

| レーザー用チラー(Laser Cooling Units)クリックするとメーカーホームページに移動します。 | |

|---|---|

|

|

Download datasheet (433 KB) Download datasheet (433 KB) |

|

Features

- Water-to-water cooling unit in 19” rack mount stainless steel case

- Cooling capacity 0 – 4 kW (at temperature difference 10 °C)

- PID controller based temperature regulation in range 15 – 35 °C, better than 0.1 °C stability

- Smooth supply water flow regulation by proportional valve

- Controlled deionizer maintains constant coolant conductivity (preset in range 1…100 µS/cm)

- Easy replaceable particle filter, accessed from front panel

- Coolant pressure can be reduced using Bypass valve

- Graphic display

- Overheat, overpressure, low flow, low coolant level warnings and error stop, error indication by LED, beeper, display, interlock connector, remote control interfaces

- Optional heater with programmable power in range 0…1 kW speeds up temperature settling at startup

- Optional USB, Ethernet interface for installation adjustment and remote control

- Optional RS232, RS485, CAN interfaces

Cooling unit PS1223CO is second generation of water-to- water cooling units designed for flashlamp-pumped lasers. Microcontroller operated PS1223CO has better performance than PS1222CO while maintaining full backward compatibility.

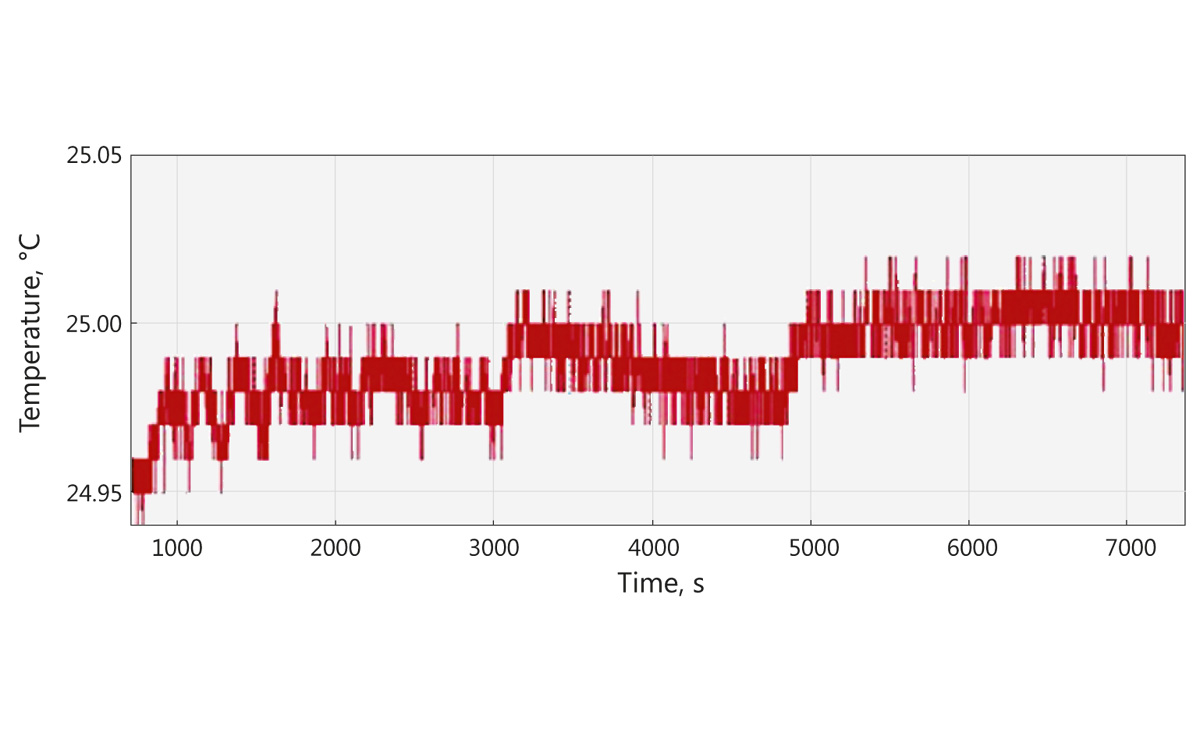

PID controller smoothly regulates water flow thru heat exchanger maintaining high stability of output temperature in a wide range of removed heat (Fig. 1). 4 digital thermometers measure temperature of coolant at output, return, tank and water supply. Coolant flow, pressure, tank water level and conductivity are also measured. Using this data microcontroller stabilizes output temperature, estimates removed heat, generates early warnings and errors. All data can be accessed by any of interface: USB, Ethernet or optional RS232, RS485, CAN. Test and adjustment utility program for Windows is included (for use with USB interface).

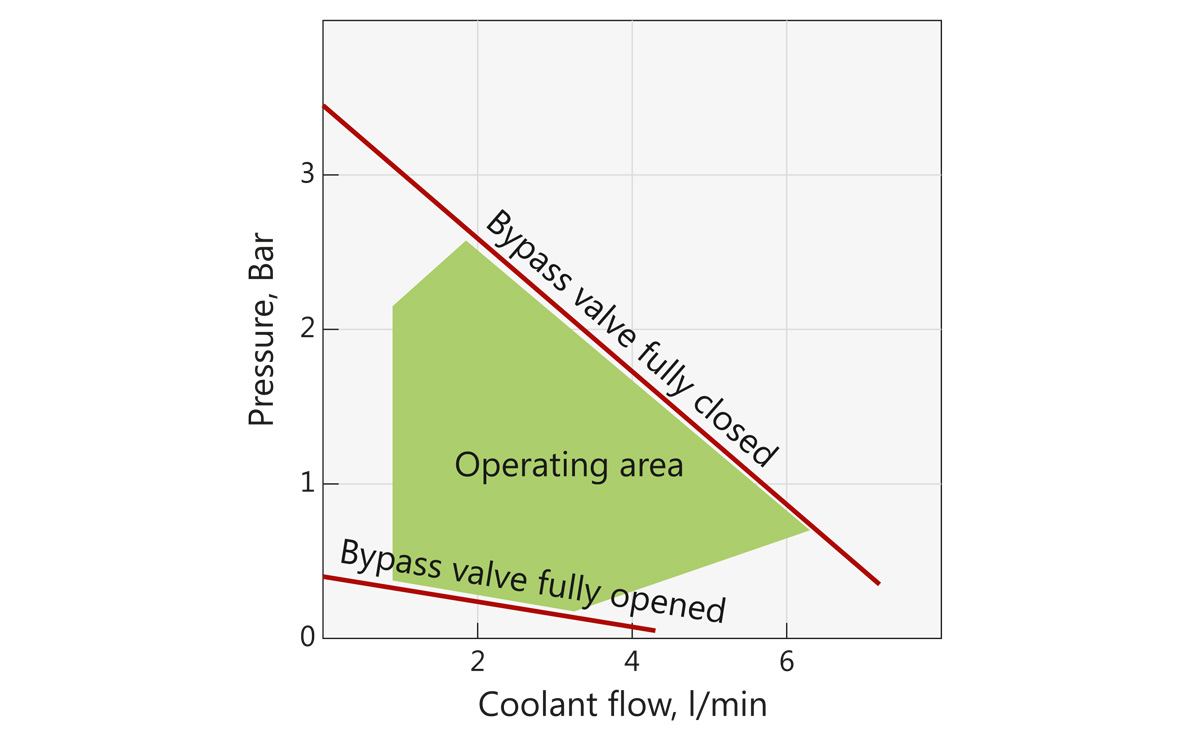

Coolant flow and output pressure can be adjusted manually using bypass valve, located inside unit and accessible when front panel is open (Fig. 2).

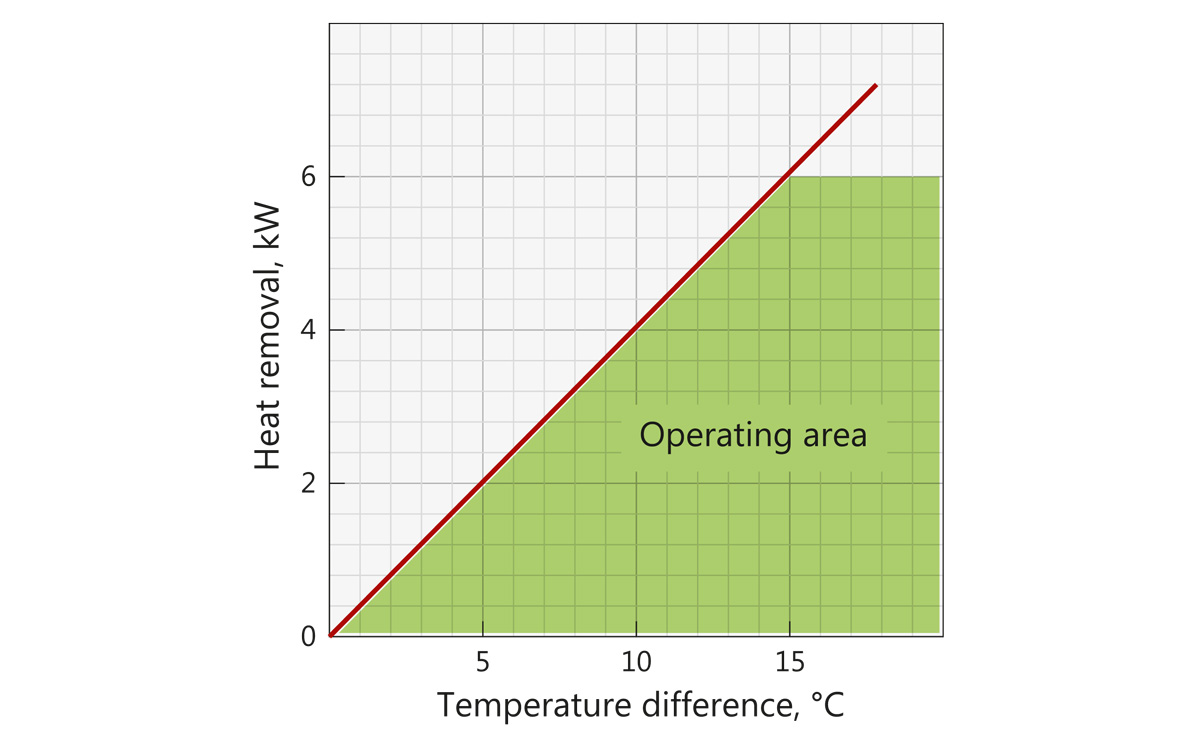

Maximum heat removal capability of the PS1223CO depends on temperature difference between coolant output temperature and supply water temperature (Fig. 3).

Fig. 1. Output temperature stability

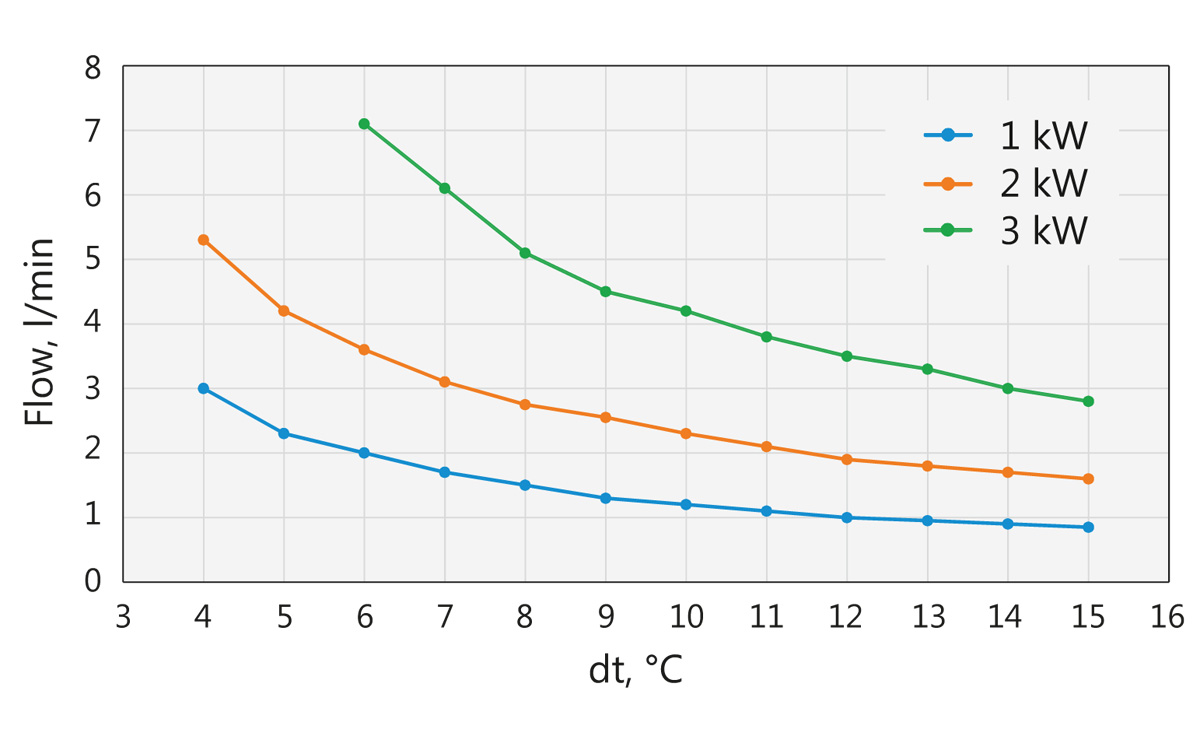

Fig. 2. Coolant pressure and flow –

operating limits

Fig. 3. Heat removal capability

Fig. 4. Water supply requirement

depending on cooling power and

temperature difference

| Model | PS1223CO |

|---|---|

| Cooling capacity at ΔT=10 °C 1) | 4 kW |

| Output temperature regulation | ±0.1 °C, (typ. ±0.05 °C) |

| Stabilization temperature range | 15 – 35 °C |

| Coolant flow range | 1 – 6 l/min |

| Maximum output pressure with bypass valve closed, zero flow | 3.0 Bar |

| Coolant | deionized or distilled water |

| Coolant reservoir capacity | 3.5 l |

| Maintained coolant conductivity | 1...100 µS/cm |

| Required water supply pressure | 1 – 8 bar |

| Required water drain pressure | <0.3 bar |

| Mains | single phase 180 – 250 V, 50/60Hz |

| Power consumption (without heater) | < 200W |

| Size | 19" 4U, depth 500 mm max. |

| Weight | < 20 kg |

1)Cooling capacity is limited by supply water consumption.

| 更新日 | 更新内容 | サイズ | ダウンロード |

|---|