Overview

Based on Cavity Ring-Down Spectroscopy (CRDS), TigerOptics Spark H2O can measure the few ppb level of moisture with absolute accuracy, proven reliability, and fast response in one compact and easy-to-use device.

Application

- Quality control for laboratory analysis

- Gas and chemical manufacturing

- R&D of moisture analysis and moisture standard

Features

- NIST traceable

- High sensitivity, high accuracy, high reliability, high speed of response

- Ease of operation, no periodic replacement/maintenance

- Compact and extremely low cost

- H2O analysis over a vast range, H2O in N2 : 15ppb~2000ppm

- Ethernet, isolated 4-20 mA and RS-232 connectivity

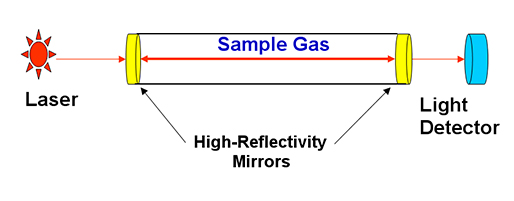

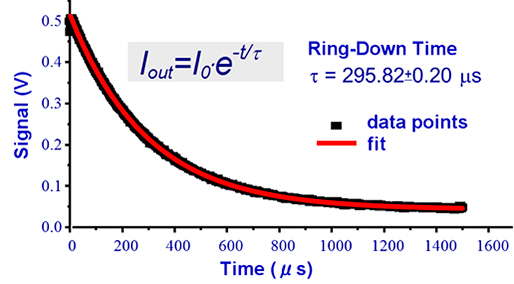

Cavity Ring-Down Spectroscopy(CRDS)

- 1.A Continuous Wave (CW) diode laser emits a directed beam of light energy through an ultra-high reflective mirror into the absorption cell (cavity).

- 2.The light reflects back and forth between two ultra-high reflective mirrors multiple times, up to a total path length of 100 kilometers.

- 3.Once the photodiode detector “sees” a preset level of light energy, the light source is shuttered or diverted from the cavity.

- 4.On each successive pass, a small amount of light or ring-down signal emits through the second mirror and is sensed by the light detector.

- 5.Once the light "rings down", the detector achieves a point of zero light energy in milliseconds, and the measurement is complete.

Fig 1. Ring-Down Cavity Cell

Fig 2. Ring-Down Time

Performance

| Operating range | See table below |

| Detection limit (LDL, 24 h peak-to-peak variation) | See table below |

| Sensitivity (3σ) | See table below |

| Precision (1σ, greater of) | ± 0.75 % or 1/3 of Sensitivity |

| Accuracy (greater of) | ± 4 % or the LDL |

| Speed of response | < 3 minutes to 90 % |

| Environmental conditions | 10 ℃~40 ℃ 30 %~80 % RH (non-condensing) |

| Storage temperature | -10 ℃~50 ℃ |

Gas Handling System and Conditions

| Wetted materials | 316L stainless steel, 10 Ra surface finish |

| Gas connections | 1/4” male VCR inlet and outlet |

| Inlet pressure | 10~125 psig (1.7~9.6 bara) |

| Flow rate | <1.4 slpm |

| Sample gases | Most inert, toxic, and passive matrices |

| Gas temperature | Up to 60 ℃ |

Dimensions and Weight

| Electronics unit and sensor, H×W×D [in (mm)] | 8.75×8.5×23.6 (222×216×599) |

| Sensor rack, H×W×D [in (mm)] | 8.75×19×23.6 (222×483×599) (fits up to two sensors) |

| Weight, standard sensor | 32 lbs (14.5 kg) |

Electrical

| Alarm indicators | 2 user programmable, 1 system fault, Form C relays |

| Power requirements | 90~240 VAC, 50/60 Hz |

| Power consumption | 40 Watts max. |

| Signal output | Isolated 4−20 mA per sensor |

| User interfaces | 5.7” LCD touchscreen, 10/100 Base-T Ethernet, 802.11g Wireless (optional), RS-232 |

Environmental Molecular Contaminant Monitor Tiger-i series

Trace Level Moisture Analyzer Spark H2O

| Sample Gas, H2O | Range | LDL | Sensitivity |

|---|---|---|---|

| In N2 | 0~2000 ppm | 15 ppb | 12 ppb |

| In O2 | 0~1000 ppm | 7 ppb | 6 ppb |

| In Ar | 0~900 ppm | 6 ppb | 4.5 ppb |

| In He | 0~450 ppm | 4 ppb | 3 ppb |

| In H2 | 0~1750 ppm | 10 ppb | 7.5 ppb |

| In Dry Air (CDA) | 0~1800 ppm | 14 ppb | 10 ppb |

| In Ne | 0~450 ppm | 40 ppb | 30 ppb |

| In Kr | 0~1100 ppm | 7 ppb | 5.5 ppb |

| In Xe | 0~1300 ppm | 10 ppb | 7.5 ppb |

| Last Updated | Update Information | Size | Download |

|---|